摄像头图卡光箱增距镜,灯箱细分行业 —多年专注摄像头测试行业,为客户提供更多选择 —

分类 | 具体内容 |

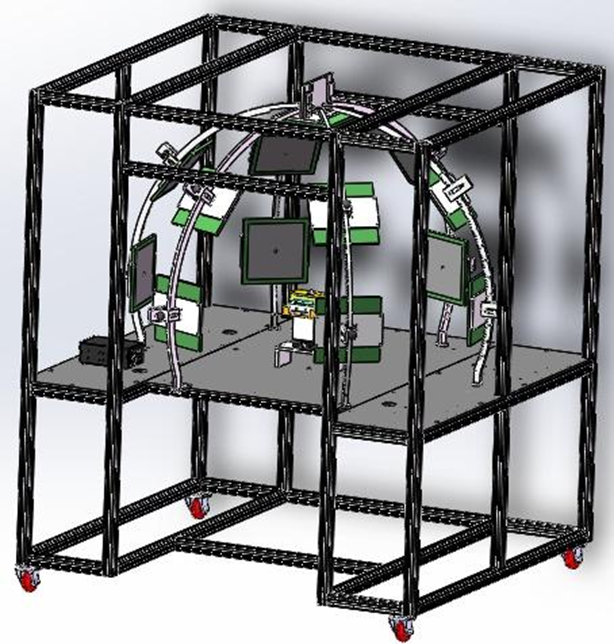

核心用途 | 用于全景摄像头调焦、终检环节的清晰度测试,精准匹配光学性能检测需求,保障测试精度,提升产品出厂良率 |

关键技术参数 | 测试距离:60cm(支持固定距离清晰度标定) 导轨设计:机加工黑色弧形导轨,自带刻度标识(便于精准定位与操作) 光源配置:13 个 200mm×200mm 光源板;亮度调节 0~5000lux;色温 5100K(接近自然光) 治具功能:支持 XYZ 三轴方向调整(适配不同型号摄像头) 外形尺寸:140cm×140cm×180cm(长 × 宽 × 高) 环境适配:配备黑色遮光布(隔绝外界光线干扰) |

结构特点 | 1. 精准定位结构:机加工弧形导轨 + 清晰刻度,减少人工定位误差 2. 稳定光源系统:13 块光源板均匀分布,亮度可调 + 自然色温,避免测试失真 3. 灵活适配治具:三轴可调,兼容多型号,降低测试成本 4. 遮光防护设计:黑色遮光布搭建封闭空间,确保数据重复性与可靠性 |

适用场景 | 1. 全景摄像头生产线调焦校准环节 2. 全景摄像头出厂终检清晰度检测环节 3. 实验室全景摄像头光学性能研发测试环节 4. 车载领域:360° 环视系统摄像头检测(模拟强光 / 暗光环境) 5. 安防领域:不同时段监控摄像头清晰度测试(隔绝杂光) 6. 工业检测领域:产线缺陷检测摄像头校准(精准定位) 7. VR/AR 领域:沉浸式设备全景摄像头画面畸变检测(稳定光源) |

注意事项 | 1. 使用前检查导轨刻度清晰度、光源板点亮状态,确保测试距离精准 2. 亮度调节需逐步进行,避免强光损伤摄像头感光元件 3. 遮光布需完全覆盖设备缝隙,防止外界光线干扰 4. 定期清洁光源板表面灰尘,保持光源输出稳定 |

Category | Details |

Core Purpose | Designed for focusing and final inspection of panoramic cameras, it accurately meets the optical performance testing requirements, ensures testing precision, and improves the outgoing qualified rate of products. |

Key Technical Parameters | Testing Distance: 60cm (supports fixed-distance sharpness calibration) Guide Rail Design: Machined black arc-shaped guide rail with built-in scale marks for precise positioning and operation during testing Light Source Configuration: 13 pieces of 200mm×200mm light source boards; Brightness adjustment range: 0~5000lux; Color temperature: 5100K (close to natural light) Fixture Function: Supports XYZ three-axis adjustment (compatible with different models of cameras) Overall Dimensions: 140cm×140cm×180cm (L×W×H) Environment Adaptability: Equipped with black light-shielding cloth (isolates external light interference) |

Structural Features | 1. Precise Positioning Structure: Machined arc-shaped guide rail with clear scales to reduce manual positioning errors 2. Stable Light Source System: 13 evenly distributed light source boards with adjustable brightness and natural color temperature to avoid test distortion 3. Flexible Adaptable Fixture: Three-axis adjustable design, compatible with multiple models, reducing testing costs 4. Light-shielding Protection Design: Black light-shielding cloth builds a closed testing space to ensure the repeatability and reliability of test data |

Application Scenarios | 1. Production Line Scenarios: Focusing calibration and final inspection sharpness testing of panoramic cameras 2. R&D Scenarios: Optical performance research and testing of panoramic cameras in laboratories 3. Automotive Field: Testing of 360° surround view system cameras (simulates strong light/low light environments) 4. Security Field: Sharpness testing of surveillance cameras in different time periods (isolates stray light) 5. Industrial Testing: Calibration of defect detection cameras on production lines (precise positioning) 6. VR/AR Field: Distortion testing of panoramic camera images for immersive devices (stable light source) |

Notes | 1. Before use, check the clarity of guide rail scales and the lighting status of light source boards to ensure accurate testing distance 2. Adjust brightness gradually to avoid damage to camera photosensitive components caused by strong light 3. Fully cover the gaps of the equipment with light-shielding cloth to prevent external light interference 4. Regularly clean dust on the surface of light source boards to maintain stable light output |